Part of the website is being upgraded and maintained.

Sep 11, 2025

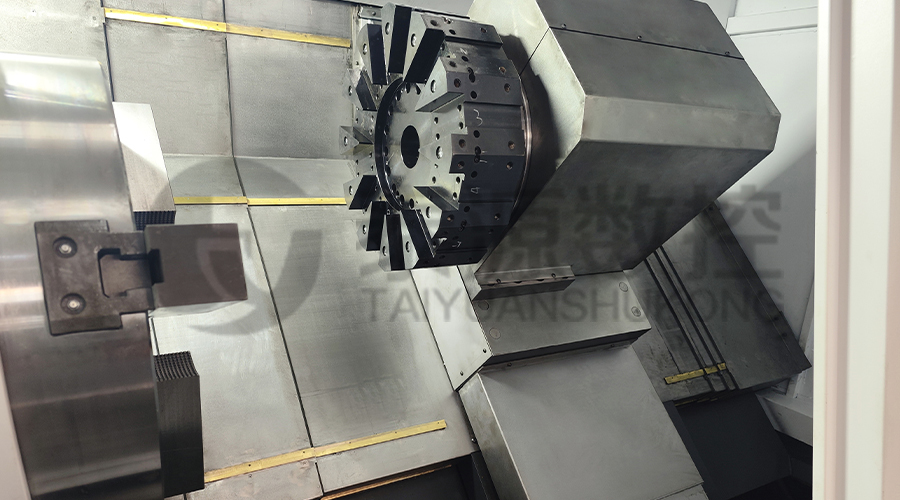

CNC machine tools play a vital role in the production and maintenance of oil and gas equipment. These high-precision machines are used to create parts and components that are essential for drilling, extraction, and refining processes in the oil and gas industry. The oilfield industry demands machinery with extreme durability and precision, making CNC machining a necessity for both manufacturing and maintenance. In this guide, we will explore the best CNC machine tools for oil and gas equipment, their key features, and how to choose the right one for your needs.

CNC machine tools offer several features that make them ideal for oil and gas equipment manufacturing. These features include high precision, exceptional durability, and efficiency in producing complex parts. The following are some of the key features that set CNC machines apart in the oil and gas sector:

Drilling is one of the most critical processes in oil and gas extraction. CNC machines are employed to create high-quality drilling equipment such as drill bits, casings, and rig components. These machines are particularly beneficial in drilling operations because of their ability to produce parts with a high degree of precision.

CNC machining is also crucial in fabricating components for oil extraction machinery, including pumps, valves, and pressure vessels. These parts must be made with high precision to ensure their reliability in extracting oil from deep underground reservoirs.

When choosing CNC machine tools for oil and gas equipment manufacturing, several factors must be considered, including the type of equipment being produced, production volume, and required precision. The choice of machine can greatly impact the efficiency and cost-effectiveness of the manufacturing process. Below are some key considerations when selecting CNC machines for oil and gas equipment.

When selecting a CNC machine for oil and gas equipment, it's crucial to balance precision with production efficiency. The ideal machine should provide both, ensuring that parts are made to exacting standards while maintaining a quick production timeline. Below is a comparison of different CNC machines based on precision and efficiency:

| Machine Type | Precision | Efficiency |

| Vertical Machining Center | High | Medium |

| Horizontal CNC Machine | Medium | High |

| Multi-axis CNC Machine | Very High | High |

The best CNC machine tools for oil and gas equipment are those that offer high precision, durability, and efficiency. Machines like vertical machining centers, horizontal CNC machines, and multi-axis CNC machines are widely used in the industry.

CNC machines improve the production of oilfield equipment by providing high precision, reducing production times, and ensuring that components are made to exact specifications. These machines are crucial for manufacturing parts that must withstand the harsh conditions in the oil and gas industry.

Key factors to consider when choosing CNC machines for oil equipment include the type of oilfield operation, required precision, production volume, and machine durability. These considerations will help ensure that the selected machine meets the specific needs of the oil and gas industry.