When you are in the market to procure a skiving machine specifically for PTFE film, choosing the right supplier matters profoundly. A sub‑optimal partner can lead to extended downtime, higher maintenance cost and process inefficiencies. In this guide, we leverage our deep experience in manufacturing and supplying precision machine tools to walk you through how to pick a top‑tier partner. We will reference critical indicators, compare supplier options, and provide actionable checklists so that you can evaluate any vendor who offers you a PTFE film skiving machine supplier for thin film production.

1. Understand Your Application & Production Needs

Define film thickness, width and throughput requirements

- Specify the minimum and maximum film thickness you intend to skive (for example 0.02 mm to 5 mm). Many machines support a range like this.

- Confirm the maximum width of film or billet diameter you will process.

- Estimate throughput: how many metres or square metres per hour you need.

Material and process compatibility

- Ensure the supplier's machine is designed for PTFE blocks (e.g., billet diameter, machine feed design) — for example some machines are described for PTFE film skiving.

- Check process details: skiving thickness precision, cutter system, spindle stability, adjustment increments.

Production volume and flexibility for future batches

- If you foresee larger production runs or different widths/thicknesses later, ensure the supplier can scale — this aligns with selecting a PTFE film skiving machine supplier for high‑precision films.

- Ask about change‑over time and how adaptable the machine is for different PTFE film grades or custom finishes.

2. Evaluate Supplier Experience & Reputation

Supplier track record in PTFE film skiving machine sector

- Check how many years the supplier has provided equipment in the skiving domain.

- Ask for machines installed specifically for PTFE film applications (not generic plastics) to ensure they understand the nuances of PTFE.

Case studies, reference customers and geographic coverage

- Request references of past customers in similar industries (e.g., insulation, non‑stick films) and check their feedback.

- A supplier delivering globally shows they understand logistics, service, and standards across geographies — which is part of being a reliable reliable PTFE film skiving machine manufacturer and supplier.

Long‑term support capability for machines

- Choose a supplier who is stable, financially sound, and offers service beyond the sale — such as spare parts, retrofits, upgrades.

- Ask: "If I purchase this machine, will you still service it in 5 or 10 years?"

3. Review Technical Specifications & Machine Performance

Key technical metrics to check

- Thickness range (minimum to maximum skivable film thickness) — e.g., some machines cover 0.025‑5 mm.

- Maximum billet diameter (for skiving) and feed precision (e.g., 0.001 mm steps).

- Skiving speed, surface finish quality, repeatability and flatness of film.

Compare machines from different suppliers

| Specification |

Supplier A |

Supplier B |

| Thickness range |

0.02‑4 mm |

0.05‑5 mm |

| Billet diameter |

Max 500 mm |

Max 800 mm |

| Thickness increment |

0.005 mm |

0.001 mm |

| After‑sales service location |

Domestic only |

Global support network |

Customization capabilities and scalability

- Check whether the supplier offers modifications (e.g., for wider film widths, special materials, integration of automation) — this goes toward choosing a PTFE film skiving machine supplier with after‑sales service.

- Ask about future upgrade paths: adding automation, online monitoring, faster throughput.

4. Quality Assurance, Certifications & After‑Sales Service

Quality system certifications

- Check for certifications such as ISO 9001 or equivalent quality management systems — as quality of machine tools depends strongly on manufacturing discipline.

- Ask for inspection reports, production test data, and past warranty claims.

Spare parts, maintenance and service response

- Ensure the supplier stocks key components and offers timely service support locally or regionally.

- Verify lead time for spare parts, especially for critical elements like cutters, bearings, spindle parts.

Warranty, lifecycle support and machine uptime

- Look for warranty terms covering both mechanical and electronic components.

- Calculate expected uptime, mean time between failures (MTBF), and whether the supplier offers preventive maintenance programs.

5. Cost, Total Cost of Ownership (TCO) & Supplier Terms

Initial purchase price vs. operational cost

- Don't just look at the cheapest quote — operational costs (energy, wear parts, downtime) matter more over the machine's life.

- Calculate expected life of the machine, expected maintenance cycles, and how quickly you can recoup investment.

Payment terms, lead time and delivery logistics

- Negotiate payment milestones, delivery schedule, installation and commissioning included.

- Check whether freight, customs, local installation/training are included or extra.

Long‑run cost factors such as maintenance, downtime, upgradeability

| Cost Factor |

Supplier A |

Supplier B |

| Energy consumption (kW/h) |

12 kW |

10 kW |

| Annual maintenance cost |

US$8,000 |

US$6,000 |

| Expected machine life (years) |

8 years |

10 years |

| Upgrade compatibility |

Limited |

Modular |

Choosing a cost‑effective partner means selecting a vendor who is not just low cost up front, but offers low cost over the full lifecycle: exactly what you'll seek in a cost‑effective PTFE film skiving machine supplier for small batch runs.

6. Selection Checklist & Decision‑Making Framework

Checklist of questions to ask suppliers

- Do you have installed machines specifically for PTFE film skiving? Provide reference contacts.

- What is the machine's minimum/maximum film thickness, billet diameter, and width capability?

- What is your service response time, spare parts lead time, and technician availability?

- Which certifications do you hold? What do test reports show regarding precision, repeatability, flatness?

- What is the total cost of ownership over 10 years, including maintenance, consumables, downtime? Provide a breakdown.

- What are your payment terms, delivery lead time, installation, training included or optional?

- How scalable/flexible is your machine if our production needs expand or shift?

Scoring/weighting method for supplier evaluation

- Assign weights to key criteria (e.g., Experience 20 %, Technical Spec 25 %, Service 20 %, TCO 25 %, Delivery/Terms 10 %).

- Score each supplier on each criterion (e.g., 1‑5 scale) and compute weighted total.

- Shortlist the top two and request a live demo or site‑visit of an installed machine.

How to shortlist and make final decision

- Ensure you have visited at least one reference site or seen machine in operation.

- Negotiate final contract including machine spec sheet, acceptance test, training, support terms, spare parts list and warranty.

- Agree on installation schedule, operator training, and performance acceptance criteria.

Company Introduction

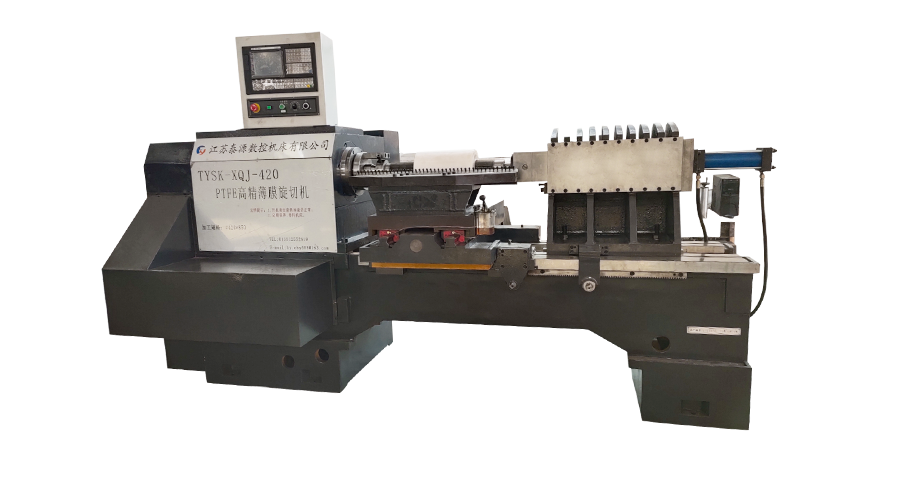

Jiangsu Taiyuan CNC Machine Tool Co., Ltd. was established in 2003. It is located in the East Industrial Park of Taixing City (Taixing is the hometown of ginkgo in China, in the central Jiangsu region and beside the golden waterway of the Yangtze River). The company covers an area of 24,800 ㎡ and a construction area of 7,900 ㎡, acting as a production base for special machine tools in the national petroleum equipment manufacturing industry.

The products mainly include: coupling CNC pipe threading lathe; drill pipe production line and its processing equipment; drill pipe inner hole and outer circle grinding machine; drill collar outer circle lathe; drill collar deep hole drilling machine; drill collar thread lathe; drill collar spiral groove, hexagonal and square CNC milling machine; screw pump rotor milling machine; drill pipe joint, drill pipe centralizer wear‑resistant belt surfacing machine; screw drill tool rotor milling machine; bent shell turning machine; bent shell pipe threading machine; mandrel threading lathe and other special machine tools.

Our company has obtained the GBT and ISO quality system certification and the national quality trustworthy enterprise label. Products are reliable in quality, high in technology, high in driving power, good in rigidity, simple in structure, strong in specificity, long in precision retention time, few in failure points, high in production efficiency, and widely used in oil fields, geology, mining, chemical and other industries.

At present, they have been widely used by many domestic and international enterprises, and are deeply loved by the majority of users. We adhere to the concept of "based on energy equipment, looking at the global peers, specialization, refinement and strengthening", and look forward to sharing development with you to create a better future!

Conclusion

Selecting the right supplier for your PTFE Film Skiving Machine Suppliers need is not merely a transaction—it is the start of a longterm strategic partnership. By carefully understanding your production needs, evaluating supplier experience and reputation, reviewing technical specs, assuring quality and service, and analysing total cost of ownership, you position yourself for success. Whether you prioritise thin film precision, small batch flexibility or high throughput, the right supplier will make a difference. Use the checklist and framework above to guide your decision, and consider engaging a supplier who aligns not only with your current needs but with your future growth as well.

FAQ

- Q1: What minimum film thickness range should I require from a PTFE film skiving machine? A1: A good machine should handle from about 0.02 mm up to 5 mm (or more depending on supplier) and offer precise increments. Checking the spec ensures it meets your application.

- Q2: Why is supplier experience important when choosing a PTFE film skiving machine supplier? A2: Because PTFE has special behaviour (low friction, high temperature resistance) and skiving it requires precision. A supplier experienced in PTFE thin films will have proven machines and service support for that material.

- Q3: How should I evaluate total cost of ownership (TCO) when comparing suppliers? A3: Beyond upfront cost, include energy consumption, maintenance/consumables cost, downtime risk, upgrade potential and machine lifetime in your comparison.

- Q4: What after‑sales service features matter for a good supplier of PTFE skiving machines? A4: Availability of spare parts, service technicians, machine training, warranty terms, local support network, and willingness for future upgrades are crucial.

- Q5: If my production volume is small today but may grow, what should I look for in a supplier? A5: Look for a supplier offering scalable machines, modular options, flexibility in film width/thickness, and a partner mindset rather than one‑time sale—this is the essence of choosing a cost‑effective PTFE film skiving machine supplier for small batch runs.