Part of the website is being upgraded and maintained.

information to be updated

In the rapidly evolving landscape of 2026 industrial manufacturing, the demand for precision in energy infrastructure has reached an all-time high. For facilities engaged in large-scale production, the choice between tra...

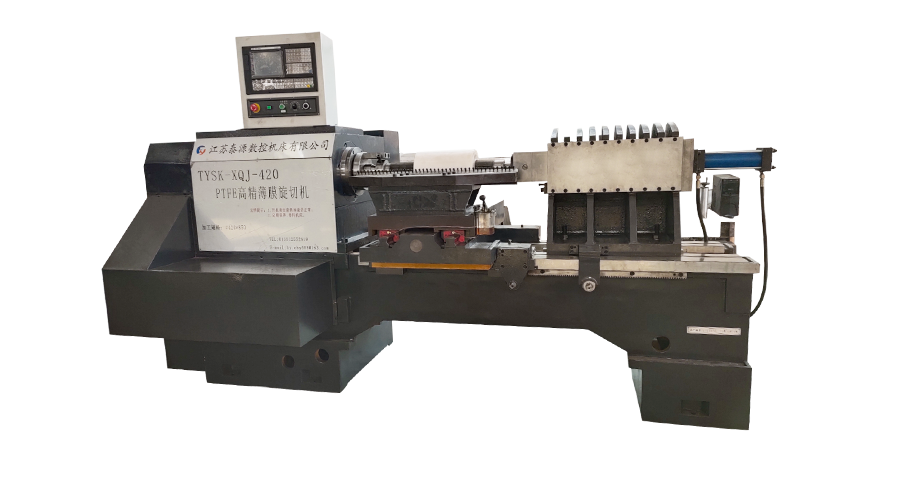

In the high-precision manufacturing of fluoropolymer films, maintaining structural integrity at velocity is the ultimate engineering challenge. A Medium & Large PTFE Film Skiving Machine must handle significant rotat...

In the high-stakes environment of oilfield exploration, the longevity of drill pipes and tool joints is directly dependent on the quality of hardbanding applied to resist downhole abrasion. A semi-automatic wear-resistan...

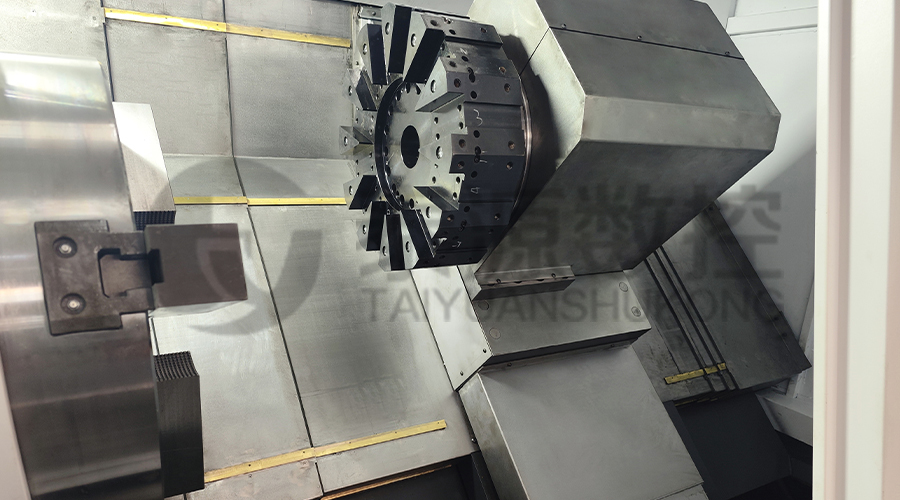

Taiyuan CNC, as a leading domestic CNC machine tool manufacturer, is well aware of the importance of fault warning systems in highly automated production environments. Therefore, the company's automatic production line is not only equipped with an advanced fault warning system, but also an intelligent solution based on the deep integration of big data analysis and Internet of Things (IoT) technology. The system can monitor various key parameters on the production line in real time, including but not limited to equipment vibration, temperature, current, voltage, and processing accuracy, and predict potential fault points through algorithm models, so as to issue warnings before the fault occurs, greatly reducing the risk of downtime caused by sudden faults.

The core of this fault warning system lies in its data analysis capabilities. The system can collect and analyze historical fault data, combine the current operating status, identify abnormal patterns, and provide accurate fault prediction reports for the maintenance team. In addition, the system also has self-learning capabilities, which can continuously optimize the prediction model, improve the accuracy of warnings, and ensure the stable operation of the production line. With deep industry experience and expertise, Taiyuan CNC's technical team has continuously upgraded the early warning system to make it more in line with actual production needs, reflecting the company's continued investment and leading position in technological innovation.

When the fault warning system issues an early warning or a production line actually fails, Taiyuan CNC takes a series of efficient and systematic response measures to respond quickly, minimize downtime, and ensure production continuity.

Immediate response mechanism: Taiyuan CNC has established a 24-hour emergency response team to ensure that the emergency plan can be immediately activated once a fault report is received, no matter when and where. The team members are composed of experienced engineers and technicians who are familiar with the structure and working principle of various machine tools and can quickly locate the problem.

Remote diagnosis and technical support: Using the remote monitoring and diagnosis system, technicians can make preliminary diagnosis of faulty equipment without interrupting production. This capability is due to Taiyuan CNC's deep accumulation in Internet of Things technology, which enables the maintenance team to remotely access equipment data, quickly determine the type and severity of the fault, and provide precise guidance for subsequent on-site maintenance.

Modular spare parts inventory: In order to reduce maintenance time, Taiyuan CNC has established a complete spare parts management system to maintain sufficient modular spare parts inventory for common faulty parts. Once it is confirmed that a part needs to be replaced, the spare parts can be quickly allocated to the site, greatly shortening the maintenance cycle. At the same time, the intelligent spare parts management system ensures the monitoring of the validity period of spare parts and timely replenishment, avoiding delays caused by insufficient spare parts.

Preventive maintenance plan: In addition to the fault warning system, Taiyuan CNC has also implemented a strict preventive maintenance plan. Regular comprehensive inspection and maintenance of the production line, including equipment cleaning, lubrication, calibration, etc., effectively prevents the risk of minor problems accumulated due to long-term operation from evolving into major failures. This forward-looking maintenance strategy not only improves the reliability of the equipment, but also further extends the service life of the equipment.

Employee training and skills improvement: Taiyuan CNC attaches importance to the skill training of employees, regularly organizes technical training and emergency drills to ensure that every employee can master the equipment operation and maintenance skills. By continuously improving the professional capabilities of the team, the company can be more calm and solve problems quickly and effectively when facing failures.

Continuous improvement and feedback loop: After each fault is handled, Taiyuan CNC will organize a review meeting to analyze the cause of the fault, summarize the experience and lessons, and optimize the fault warning system and maintenance process accordingly. This culture of continuous improvement ensures that the company can continue to learn from practice and improve its ability to deal with faults.