Part of the website is being upgraded and maintained.

information to be updated

In the rapidly evolving landscape of 2026 industrial manufacturing, the demand for precision in energy infrastructure has reached an all-time high. For facilities engaged in large-scale production, the choice between tra...

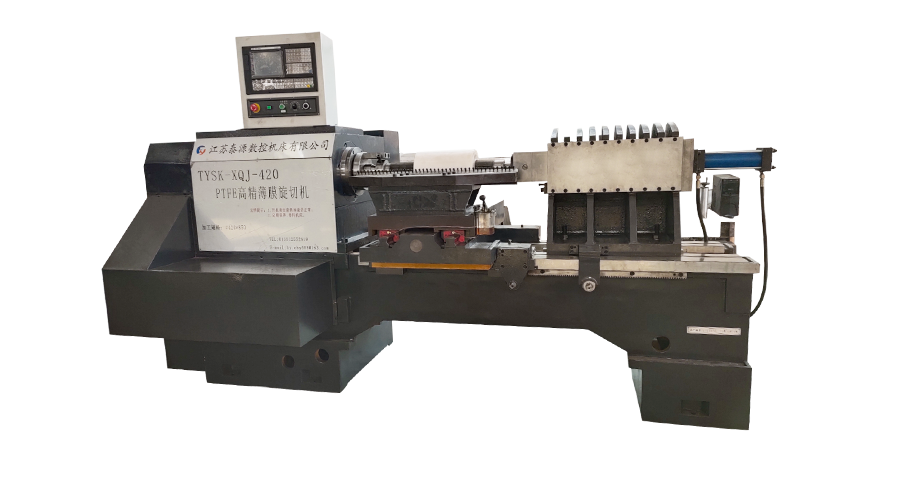

In the high-precision manufacturing of fluoropolymer films, maintaining structural integrity at velocity is the ultimate engineering challenge. A Medium & Large PTFE Film Skiving Machine must handle significant rotat...

In the high-stakes environment of oilfield exploration, the longevity of drill pipes and tool joints is directly dependent on the quality of hardbanding applied to resist downhole abrasion. A semi-automatic wear-resistan...

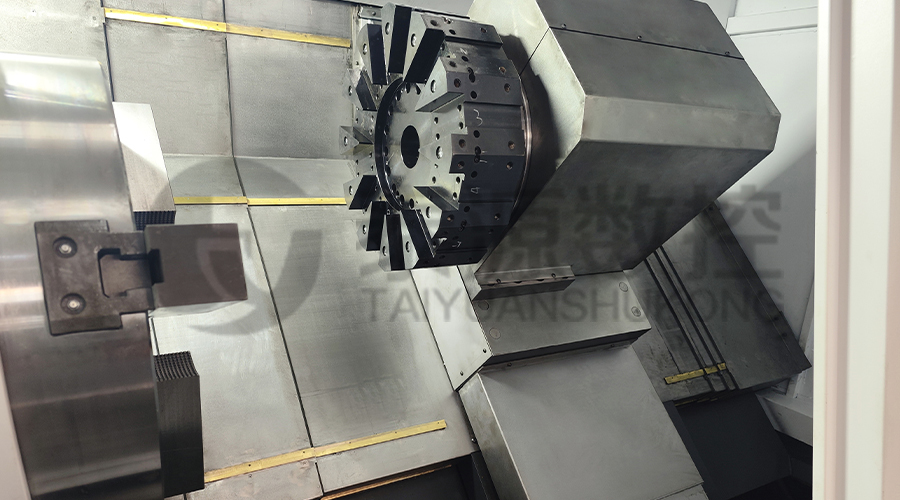

Jiangsu Taiyuan's core machine tool product lines, such as coupling CNC pipe thread lathes, drill rod inner/external cylindrical grinders, drill collar external cylindrical lathes and thread lathes, are designed to meet the high-precision requirements of coupling processing. These machine tools use a closed-loop servo control system, combined with precision ball screws and linear guides, to ensure positioning accuracy and repeat positioning accuracy during processing, providing a solid foundation for the precise matching of various components of the coupling. In addition, the high-rigidity structural design and high-power drive system of the machine tool effectively reduce processing vibration, improve processing efficiency, and ensure the surface finish and dimensional accuracy of the processed parts.

In the pursuit of higher precision, Jiangsu Taiyuan did not stop at the application of traditional machine tools, but further introduced laser processing technology. Laser cutting and marking technology, with its characteristics of non-contact, high precision and small heat-affected zone, realizes the fast and precise cutting and marking of coupling materials, and improves the surface quality and dimensional accuracy of the processed parts. Laser welding technology, with its tiny heat-affected zone, high-strength weld and good appearance quality, provides reliable guarantee for the precise docking of complex coupling structures.

When building the intelligent production line of couplings, Jiangsu Taiyuan not only focuses on improving the performance of single machines, but also emphasizes the system integration and automation level of the entire production line. By introducing advanced production management systems (such as MES, ERP, etc.), intelligent scheduling of production tasks, real-time monitoring of production progress and traceability analysis of quality data are realized. The use of automated equipment such as robots and AGV carts realizes the automatic loading and unloading and handling of raw materials, semi-finished products and finished products, reduces manual intervention, improves production efficiency, and reduces errors caused by human factors. The integration of online detection and feedback systems ensures that the key dimensions and geometric tolerances in the processing process can be monitored and adjusted in real time, further improving the processing accuracy.

Jiangsu Taiyuan CNC Machine Tool Co., Ltd. has obtained GBT, ISO quality system certification and the honor of national quality trustworthy enterprises, which is not only a recognition of the company's management system and product quality, but also a strong proof of the high-precision processing capabilities of the intelligent production line of couplings. The company strictly follows the ISO 9001 quality management system standards. From raw material procurement to production and processing, assembly and commissioning to finished product inspection, strict quality control is implemented in every link to ensure that the final delivered coupling products can meet or even exceed customer expectations.