Part of the website is being upgraded and maintained.

information to be updated

In the rapidly evolving landscape of 2026 industrial manufacturing, the demand for precision in energy infrastructure has reached an all-time high. For facilities engaged in large-scale production, the choice between tra...

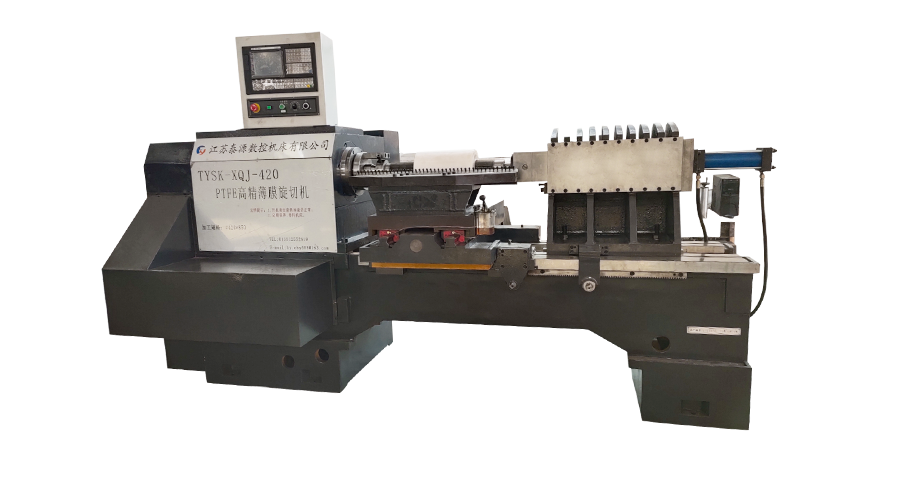

In the high-precision manufacturing of fluoropolymer films, maintaining structural integrity at velocity is the ultimate engineering challenge. A Medium & Large PTFE Film Skiving Machine must handle significant rotat...

In the high-stakes environment of oilfield exploration, the longevity of drill pipes and tool joints is directly dependent on the quality of hardbanding applied to resist downhole abrasion. A semi-automatic wear-resistan...

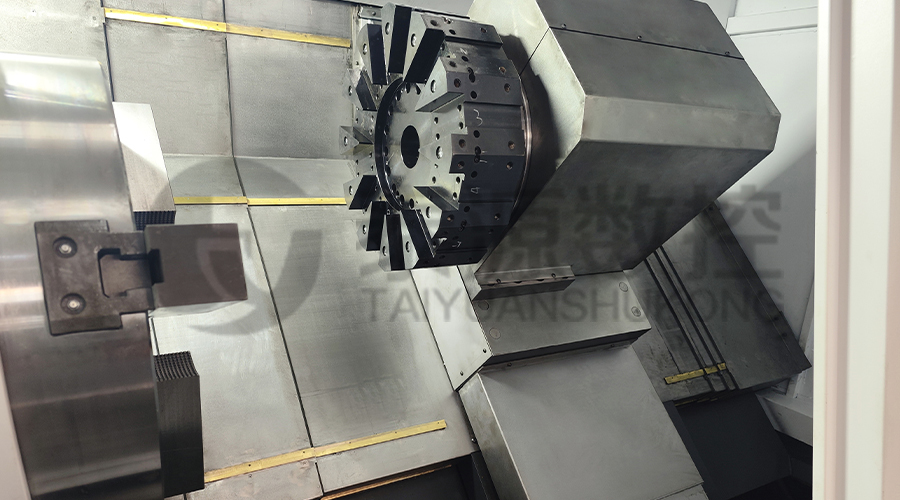

In the finishing stage, we make full use of high-performance drill pipe inner hole and outer cylindrical grinders. These machine tools, with their high-precision spindles, advanced automatic feeding systems and closed-loop control systems, achieve micron-level processing accuracy control of the inner and outer surfaces of the drill pipe joint. By real-time monitoring and adjustment of grinding parameters, combined with the high rigidity and simple structure of the machine tool, the vibration error is effectively reduced and the processing stability is improved. In addition, we use a special CNC lathe, combined with advanced CNC programming technology and servo drive system, to achieve one-time forming of complex contours, ensuring the accuracy and consistency of the appearance of the drill pipe joint.

In the thread processing link, the coupling CNC pipe thread lathe has become the core equipment. The machine tool adopts advanced thread cutting algorithms, which can accurately control the pitch, tooth angle and thread depth. At the same time, high-precision sensors detect the thread morphology in real time to ensure that the thread parameters meet the design requirements. In order to further improve the sealing of threads, we have implemented a strict quality inspection process, using three-coordinate measuring machines (CMM) and thread comprehensive measuring instruments for comprehensive inspection, including key indicators such as pitch error and thread profile half-angle deviation, to ensure that each item meets international or customer-specific standards. In addition, we also use pressure testing to simulate actual working conditions to test the sealing performance of threaded joints and ensure that the products perform well in actual applications.

To ensure that each step of processing meets the established standards, we rely on the ISO quality management system to establish a full range of quality control processes from raw material procurement, production and processing to finished product inspection. Each process has strict quality control points to ensure that every step is accurate and correct. We work closely with well-known tool manufacturers to select high-performance tools, and regularly check tool wear and replace them in time to avoid processing errors caused by tool problems. In addition, we continue to increase R&D investment, introduce intelligent algorithms to optimize processing parameters, develop adaptive control systems, automatically adjust processing strategies based on real-time feedback during processing, reduce human interference, and improve processing efficiency and accuracy.

As a technology-driven enterprise, we are well aware of the importance of technological innovation. Therefore, we continue to explore the development and application of new technologies and processes, such as reducing the impact of cutting heat by optimizing tool paths, maintaining material hardness and thread surface integrity, and developing more efficient thread cutting algorithms. These technological innovations not only improve product quality, but also enhance our processing capabilities under complex working conditions, making our products widely used in oil fields, geology, mining, chemical and other industries, and winning wide praise and trust from customers.