Series:TYSK-HB

Applicable to ARNCO 100XT, 200XT, 300XT. Support φ1.2-2.0 cored or solid wire su...

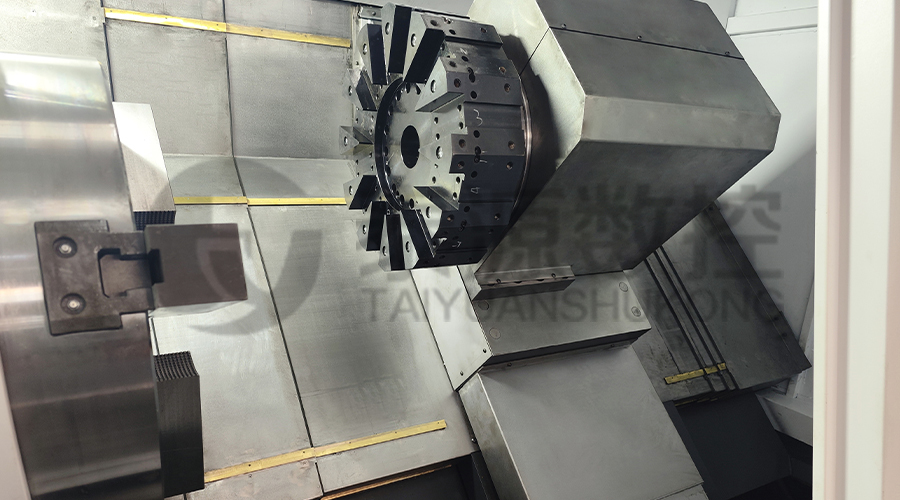

With far higher than the industry standards for producing hard banding machines.Equipped with complete process processing equipment, efficient and stable welding beautiful and reliable workpiece.

Applicable to ARNCO 100XT, 200XT, 300XT. Support φ1.2-2.0 cored or solid wire su...

In the rapidly evolving landscape of 2026 industrial manufacturing, the demand for precision in energy infrastructure has reached an all-time high. For facilities engaged in large-scale production, the choice between tra...

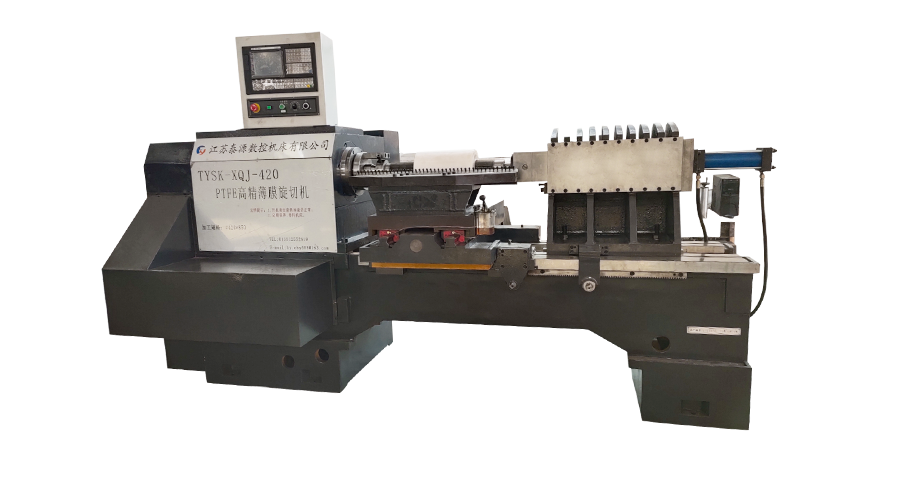

In the high-precision manufacturing of fluoropolymer films, maintaining structural integrity at velocity is the ultimate engineering challenge. A Medium & Large PTFE Film Skiving Machine must handle significant rotat...

In the high-stakes environment of oilfield exploration, the longevity of drill pipes and tool joints is directly dependent on the quality of hardbanding applied to resist downhole abrasion. A semi-automatic wear-resistan...

In modern manufacturing, CNC machine tools and their supporting equipment have become key factors in improving production efficiency and product quality. Jiangsu Taiyuan CNC Machine Tool Co., Ltd., as a leader in the industry, has not only surpassed its peers in production efficiency with its advanced semi-automatic wear-resistant band welder, but also set a new benchmark in product quality and inspection standards. This article will explore in depth how the semi-automatic wear-resistant band welder of Jiangsu Taiyuan CNC Machine Tool Co., Ltd. ensures high precision and comprehensive inspection to meet the diverse needs of customers.

1. Hard belt production machine far higher than the industry standard

The semi-automatic wear-resistant band welder provided by Jiangsu Taiyuan CNC Machine Tool Co., Ltd. has performance and standards far higher than ordinary hard belt production machines in the industry. This welding machine is not only equipped with a full range of process processing equipment, but also shows efficient and stable characteristics during the welding process, and can weld both beautiful and reliable workpieces. Its excellent wear resistance is suitable for the welding of a variety of high-strength and high-wear-resistant materials, providing strong support for manufacturing customers.

2. Strictly control each process

In Jiangsu Taiyuan's production process, there is a corresponding inspection link after each process. This strict control ensures that every step of the product in the production process meets the established quality standards. For the final product, the company conducts 100% inspection according to customer requirements and international standards to ensure that each product meets or exceeds customer expectations.

3. The most advanced testing equipment in the industry

In order to ensure that customers are provided with high-precision final castings, Jiangsu Taiyuan CNC Machine Tool Co., Ltd. is equipped with the most advanced and complete top-notch testing equipment in the industry. These equipment include but are not limited to spectrometers, metallographic microscopes, universal tensile testing machines, low-temperature impact testing machines, X-ray flaw detectors, magnetic particle flaw detectors, ultrasonic flaw detectors, three-coordinate measuring machines, and image measuring machines.

Spectrometer: used to analyze the chemical composition of materials to ensure that the materials meet the design requirements.

Metallographic microscope: observe the microstructure of the material and evaluate the organization and performance of the material.

Universal tensile testing machine: test the tensile strength and other mechanical properties of the material.

Low-temperature impact testing machine: evaluate the toughness of the material in a low-temperature environment.

X-ray flaw detector, magnetic particle flaw detector, ultrasonic flaw detector: used to detect defects and cracks inside the material.

Three-coordinate measuring machine and image measuring machine: accurately measure the geometric size and shape of the product.

The comprehensive use of these equipment not only fully guarantees the provision of high-precision final castings to customers, but also meets customers' comprehensive testing needs such as material physical and chemical properties, non-destructive testing, and high-precision geometric size testing.

Jiangsu Taiyuan CNC Machine Tool Co., Ltd. has set a new benchmark in the manufacturing industry with its semi-automatic wear-resistant band welder and its perfect testing system. The company not only pursues excellence in production efficiency and product quality, but also strictly controls the testing standards to ensure that every product meets or exceeds customer expectations. In the future, Jiangsu Taiyuan will continue to be committed to technological innovation and quality improvement to provide manufacturing customers with better quality and more efficient services.