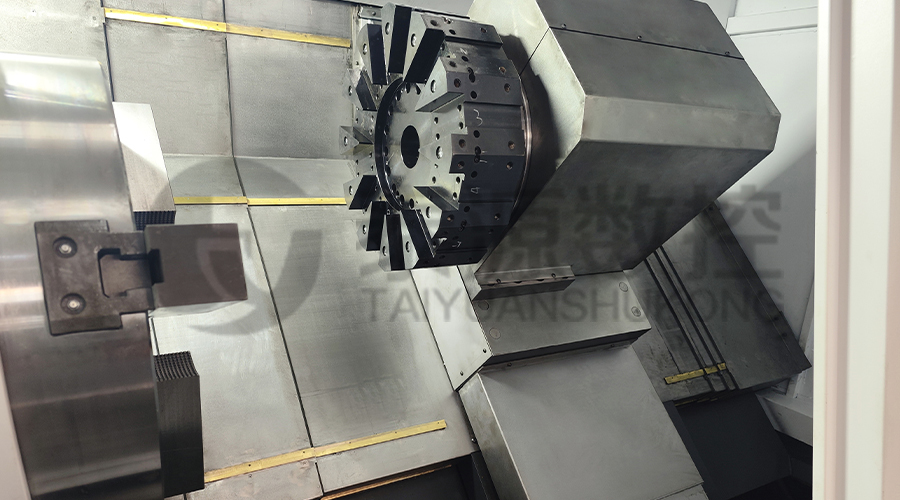

Model:TYSK-630T

The machine adopts a FANUC CNC system with stable processing accuracy and flexib...

Excellent equipment processing accuracy, good rigidity, first-class processing efficiency, so that our products can be qualified for API standards and most of the market premium connection.

The machine adopts a FANUC CNC system with stable processing accuracy and flexib...

The machine adopts a FANUC CNC system with stable processing accuracy and flexib...

In the rapidly evolving landscape of 2026 industrial manufacturing, the demand for precision in energy infrastructure has reached an all-time high. For facilities engaged in large-scale production, the choice between tra...

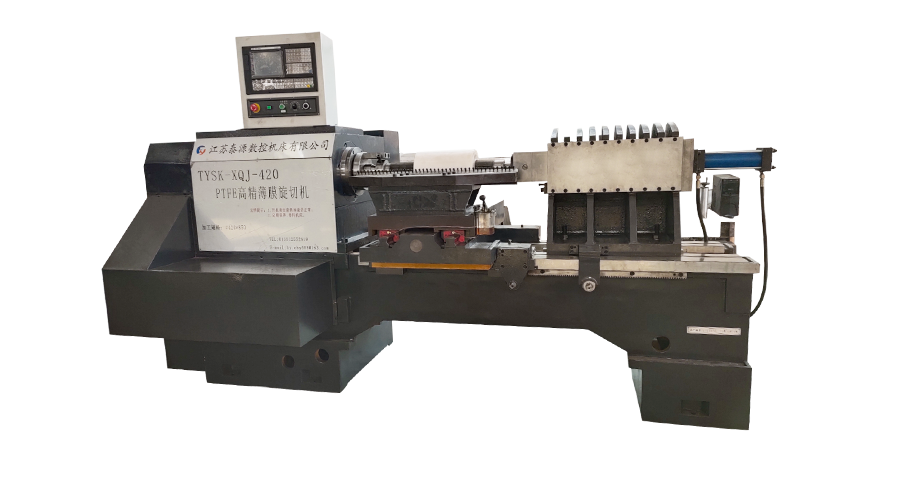

In the high-precision manufacturing of fluoropolymer films, maintaining structural integrity at velocity is the ultimate engineering challenge. A Medium & Large PTFE Film Skiving Machine must handle significant rotat...

In the high-stakes environment of oilfield exploration, the longevity of drill pipes and tool joints is directly dependent on the quality of hardbanding applied to resist downhole abrasion. A semi-automatic wear-resistan...

Jiangsu Taiyuan CNC Machine Tool Co., Ltd. has a variety of CNC machine tools for pipe processing. The following is the method of adjusting the cutting parameters of CNC Pipe Threading Lathe Machine to ensure the thread quality when processing pipes of different materials:

Processing steel pipes

Cutting speed: For pipes made of medium carbon steel, the cutting speed can be around 100-200 m/min. If it is alloy steel, due to its high hardness, the cutting speed should be appropriately reduced to about 80-150 m/min to prevent excessive wear of the tool and ensure the surface quality of the thread.

Feed rate: Usually, the feed rate per revolution is more appropriate at 0.5-1.2 mm/rev. For threads with high precision requirements, a smaller feed rate, such as 0.5-0.8 mm/rev, can be selected to improve the finish and precision of the thread.

Cutting depth: According to the specifications and requirements of the thread, the cutting depth can be controlled at 1-2 mm during rough machining and 0.2-0.5 mm during fine machining.

Processing copper pipes

Cutting speed: The hardness of copper is relatively low, and the cutting speed can be appropriately increased, generally around 200-300 m/min. However, the speed should not be too high, otherwise it may cause copper chips to wrap around the tool and affect the processing quality.

Feed rate: The feed rate can be selected between 0.8-1.5 mm/rev. Due to the good ductility of copper, a larger feed rate can reduce the cutting force and prevent excessive deformation of the material, but it should also be noted that it should not be too large to avoid affecting the thread accuracy.

Cutting depth: The cutting depth can be 1.5-2.5 mm during rough machining and 0.3-0.6 mm during fine machining.

Processing aluminum pipes

Cutting speed: Aluminum has low hardness and good cutting performance, so the cutting speed can be higher, usually 300-500 m/min. However, attention should be paid to the problem of built-up edge that may occur during high-speed cutting, which can be solved by appropriate cooling and lubrication measures.

Feed rate: The feed rate can be around 1-2 mm/rev. Since aluminum materials are softer, a larger feed rate can improve processing efficiency, but it is necessary to prevent excessive feed rate from causing defects such as scratches on the thread surface.

Cutting depth: The cutting depth can be 2-3 mm during rough processing and 0.3-0.8 mm during fine processing.

Processing stainless steel pipes

Cutting speed: Stainless steel has high strength and hardness, and is prone to work hardening. The cutting speed is generally 60-120 m/min. Too low speed will cause increased tool wear, and too high speed may cause tool burns and workpiece deformation.

Feed rate: The feed rate per revolution is generally 0.3-0.8 mm/rev. A smaller feed rate can reduce cutting force, reduce the degree of work hardening, and help ensure thread quality.

Cutting depth: The cutting depth can be controlled at 0.8-1.5 mm during rough machining and 0.1-0.3 mm during fine machining.