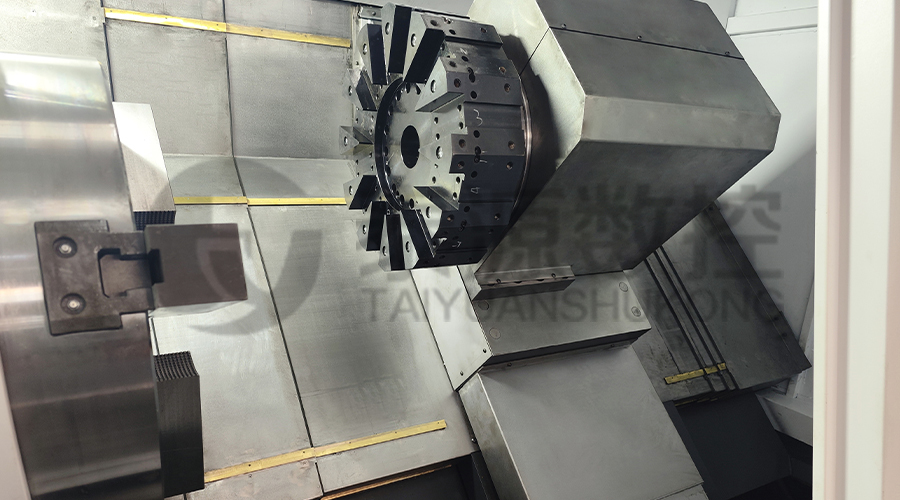

Model:TYSK-630T

The machine adopts a FANUC CNC system with stable processing accuracy and flexib...

Excellent equipment processing accuracy, good rigidity, and first-class processing efficiency, so that our products can be qualified for API standards and most of the market premium connections.

The machine adopts a FANUC CNC system with stable processing accuracy and flexib...

In the rapidly evolving landscape of 2026 industrial manufacturing, the demand for precision in energy infrastructure has reached an all-time high. For facilities engaged in large-scale production, the choice between tra...

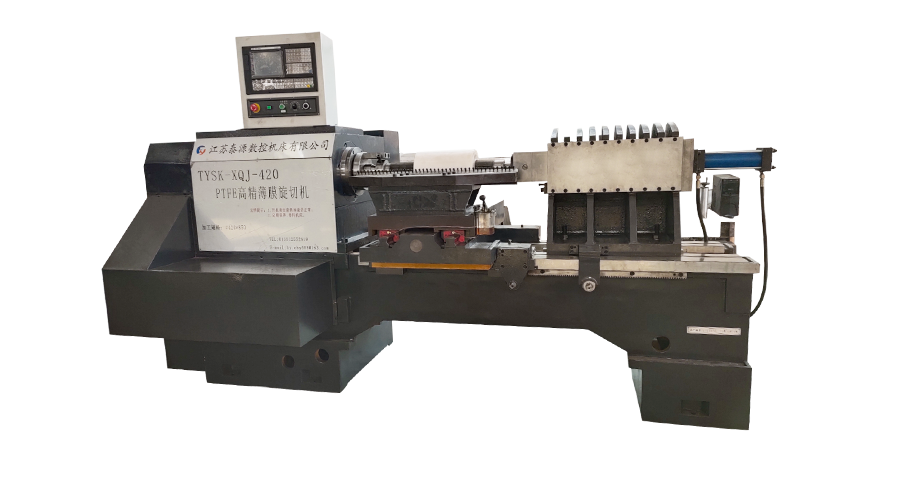

In the high-precision manufacturing of fluoropolymer films, maintaining structural integrity at velocity is the ultimate engineering challenge. A Medium & Large PTFE Film Skiving Machine must handle significant rotat...

In the high-stakes environment of oilfield exploration, the longevity of drill pipes and tool joints is directly dependent on the quality of hardbanding applied to resist downhole abrasion. A semi-automatic wear-resistan...

When operating the Joint & Coupling Lathe Machine to process drill pipe joints and couplings, the common tool wear problems and solutions are as follows:

Common tool wear problems

Abrasive wear: During the processing of drill pipe joints and couplings, hard points in the workpiece material, such as carbides, nitrides, etc., will cut and scratch the tool surface like abrasive particles, causing tool wear. Especially when processing drill pipe materials with higher hardness, abrasive wear is more obvious.

Adhesive wear: During the cutting process, there is strong friction and high temperature between the tool and the workpiece surface, causing the atoms between the tool and the workpiece material to diffuse and bond with each other. When the tool and the workpiece move relative to each other, the bonding point will be torn, causing the tool material to be taken away, forming adhesive wear. This type of wear is prone to occur when processing materials with high viscosity.

Diffusion wear: Under high-temperature cutting conditions, the chemical elements of the tool and the workpiece material will diffuse with each other, changing the chemical composition and properties of the tool material, reducing the hardness and strength of the tool, and thus aggravating the wear of the tool. Especially when cutting drill pipe joints and couplings at high speed, diffusion wear will be more serious.

Blade collapse: Since the processing of drill pipe joints and couplings usually requires intermittent cutting, such as when processing threads, the tool will be subjected to periodic impact loads. When the impact resistance of the tool is insufficient or the cutting parameters are not selected properly, the edge of the tool is prone to blade collapse, resulting in premature failure of the tool.

Thermal fatigue wear: During the cutting process, the tool is repeatedly subjected to cutting heat, generating thermal stress. When the thermal stress exceeds the fatigue strength of the tool material, cracks will appear on the tool surface. As the cracks expand and connect to each other, the tool material will peel off, forming thermal fatigue wear.

Solution

Choose the right tool material

For severe abrasive wear, carbide tools with high hardness and good wear resistance can be selected. The drill rod processing equipment produced by Jiangsu Taixing CNC Machine Tool Co., Ltd. is suitable for a variety of tools. The corresponding carbide tool model can be selected according to different processing requirements to improve the tool's resistance to abrasive wear.

For bonding wear and diffusion wear, coated tools can be used. The coating can form an isolation layer between the tool and the workpiece, reduce the direct contact between the tool and the workpiece material, and reduce the possibility of bonding and diffusion. For example, TiN coated tools have good hardness and chemical stability, which can effectively reduce bonding and diffusion wear.

Optimize cutting parameters

Reasonably adjust the cutting speed, feed rate and cutting depth. When processing drill rod joints and couplings, if the cutting speed is too high, it will aggravate the wear of the tool, especially diffusion wear and thermal fatigue wear. According to the workpiece material and tool performance, select the appropriate cutting speed. Generally speaking, for drill rod materials with higher hardness, the cutting speed should be appropriately reduced.

The feed rate should not be too large. Excessive feed rate will increase the cutting force on the tool, which is easy to cause tool chipping and increased wear. The reasonable feed rate range can be determined through experiments and experience.

The selection of cutting depth should consider the strength of the tool and the processing requirements of the workpiece, and avoid excessive cutting depth, which will cause the tool to bear excessive load.

Improve cutting conditions

Make full use of cutting fluid. Cutting fluid has the functions of cooling, lubrication, chip removal and rust prevention, which can effectively reduce the cutting temperature, reduce the friction between the tool and the workpiece, and thus reduce the wear of the tool. For the processing of drill pipe joints and couplings, cutting fluids with good extreme pressure lubrication and cooling properties should be selected, such as cutting fluids containing extreme pressure additives such as sulfur and phosphorus.

Clean the chips in the cutting area regularly to prevent the chips from accumulating between the tool and the workpiece, causing secondary wear. The equipment of Jiangsu Taixing CNC Machine Tool Co., Ltd. may be equipped with corresponding chip removal devices. Ensure its normal operation and timely discharge of chips.

Improve the quality of tool grinding

Ensure the sharpness and surface quality of the tool. A blunt edge will increase the cutting force and cutting heat, accelerate tool wear; excessive surface roughness of the tool will also increase friction and aggravate wear. Therefore, it is necessary to use appropriate grinding technology and equipment to finely grind the tool to improve the quality of tool grinding.

Sharpen and inspect the tools regularly to detect wear and damage of the tools in time, and re-sharpen or replace the tools that are severely worn to ensure processing quality and efficiency.