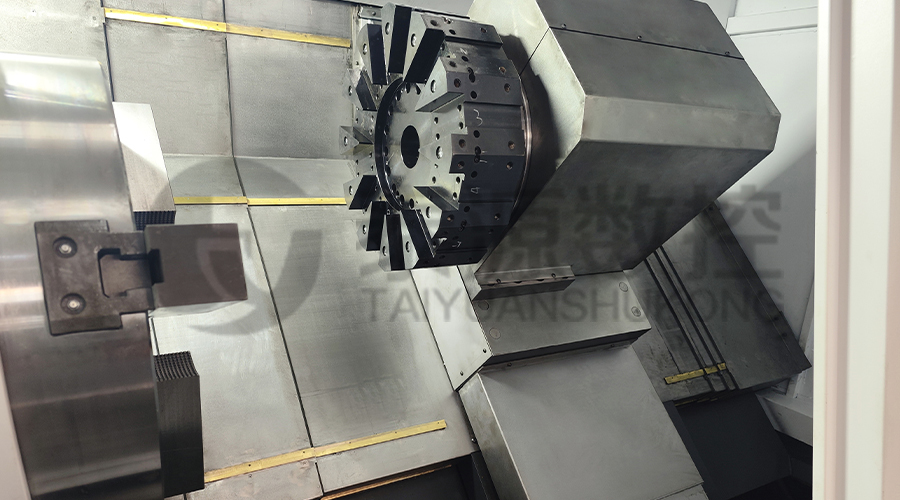

Model:TYSK-1355

The machine adopts a FANUC CNC system with stable processing accuracy and flexib...

Excellent equipment processing accuracy, good rigidity, first-class processing efficiency, so that our products can be qualified for API standards and most of the market premium connection.

The machine adopts a FANUC CNC system with stable processing accuracy and flexib...

In the rapidly evolving landscape of 2026 industrial manufacturing, the demand for precision in energy infrastructure has reached an all-time high. For facilities engaged in large-scale production, the choice between tra...

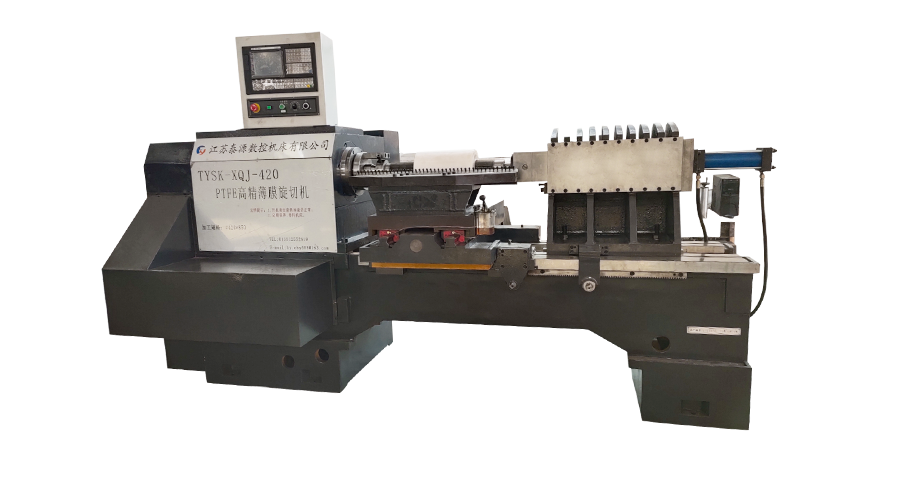

In the high-precision manufacturing of fluoropolymer films, maintaining structural integrity at velocity is the ultimate engineering challenge. A Medium & Large PTFE Film Skiving Machine must handle significant rotat...

In the high-stakes environment of oilfield exploration, the longevity of drill pipes and tool joints is directly dependent on the quality of hardbanding applied to resist downhole abrasion. A semi-automatic wear-resistan...

For the spindle system of an Oil Pipe Processing Lathe Machine in the context of Jiangsu Taiyuan CNC Machine Tool Co., Ltd., the regular inspection items usually include the following:

Spindle Rotational Accuracy

Check the radial runout and axial end play of the spindle. This is crucial as excessive runout or end play can affect the precision of oil pipe processing, leading to problems such as uneven wall thickness or inaccurate thread machining. For the drill pipe production line and its processing equipment, as well as the coupling CNC pipe threading lathe produced by Jiangsu Taiyuan, precise spindle rotational accuracy is essential to ensure the quality of pipe threading and overall pipe processing.

Bearing Condition

Examine the bearings for signs of wear, damage, or overheating. The bearings support the spindle and play a vital role in its smooth operation. Worn or damaged bearings can cause vibration and noise, and may even lead to spindle failure. In the case of drill collar outer circle lathes and drill collar deep hole drilling machines, the bearings in the spindle system need to withstand high loads and rotational speeds, so regular inspection is necessary to prevent bearing failures that could affect the processing of drill collar.

Lubrication System

Check the lubricant level, quality, and circulation. Adequate and clean lubrication is necessary to reduce friction and heat generation in the spindle system. Insufficient or contaminated lubricant can cause increased wear and reduced spindle life. For example, in the screw pump rotor milling machine and drill pipe joint surfacing machine, the spindle system's lubrication is critical to ensure the smooth operation of the milling and surfacing processes.

Spindle Motor

Inspect the motor for proper operation, including checking for abnormal noises, vibrations, and temperature rise. The spindle motor provides the power for spindle rotation, and any issues with it can directly affect the processing efficiency and quality. In the case of the mandrel threading lathe and other special machine tools, the spindle motor must operate stably to ensure accurate threading of the mandrel.

Spindle Cooling System

Check the cooling system for proper functioning, including the coolant flow, temperature control, and presence of leaks. Cooling is important to prevent the spindle from overheating during high-speed operation, which can affect its accuracy and performance. For the bent shell turning machine and bent shell pipe threading machine, the spindle cooling system is especially important as these machines may operate under high-load and high-temperature conditions during the processing of bent shells.