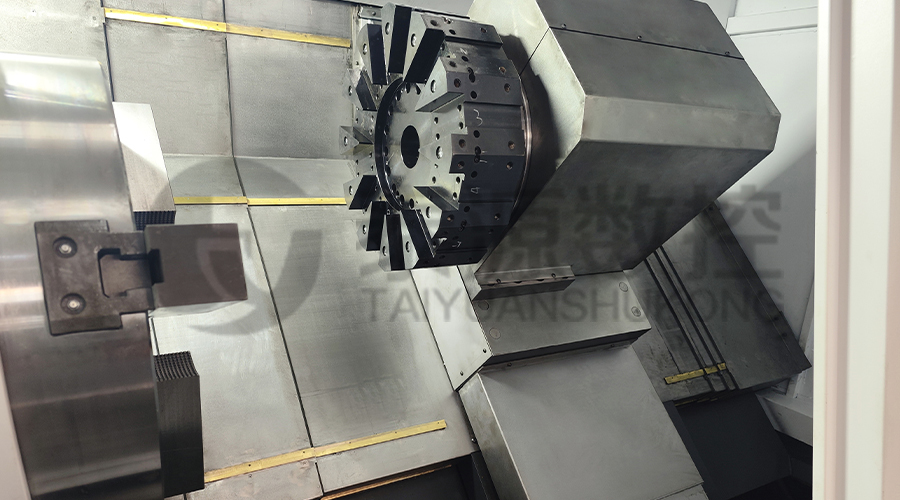

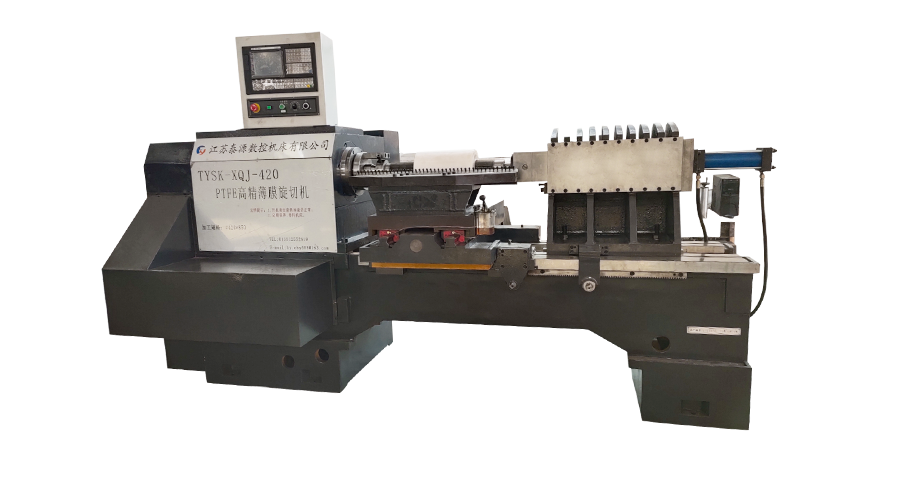

Model:TYSK-XQJ-550

Designed to process blanks with a maximum diameter of 550 mm and a maximum lengt...

With 20 years of heavy CNC lathe manufacturing experience, we have accumulated unique manufacturing advantages.

Designed to process blanks with a maximum diameter of 550 mm and a maximum lengt...

In the rapidly evolving landscape of 2026 industrial manufacturing, the demand for precision in energy infrastructure has reached an all-time high. For facilities engaged in large-scale production, the choice between tra...

In the high-precision manufacturing of fluoropolymer films, maintaining structural integrity at velocity is the ultimate engineering challenge. A Medium & Large PTFE Film Skiving Machine must handle significant rotat...

In the high-stakes environment of oilfield exploration, the longevity of drill pipes and tool joints is directly dependent on the quality of hardbanding applied to resist downhole abrasion. A semi-automatic wear-resistan...

PTFE is a material with excellent corrosion resistance, low friction coefficient, good self-lubrication, heat resistance and electrical insulation. However, its stiffness, hardness and strength are relatively small, with a tensile strength of 21~28 MPa, a bending strength of 11~14 MPa, an elongation of 250%~300%, and a small thermal conductivity of only 0.27W/M·K, and a relatively low heat resistance temperature. These properties make PTFE prone to softening and sticking during the cutting process, and put forward special requirements for the tool material and cutting process.

In view of these characteristics of PTFE film, the choice of tool material is crucial. Jiangsu Taiyuan CNC Machine Tool Co., Ltd. usually uses carbide tools for the tool material of PTFE film peeling machines. Carbide tools are ideal for cutting PTFE films due to their high hardness, high wear resistance and good thermal stability. Compared with high-speed steel tools, carbide tools show better performance and longer service life when cutting PTFE.

High hardness and wear resistance:

The high hardness of carbide tools can easily cope with the cutting of PTFE film, reduce tool wear and extend service life.

During the long-term cutting process, the wear resistance of carbide tools ensures the stability and consistency of cutting quality.

Good thermal stability:

PTFE film is easy to soften and stick to the knife during the cutting process, while carbide tools have good thermal stability, which can maintain the hardness and sharpness of the tool at high temperatures and reduce the occurrence of sticking.

At the same time, the thermal stability of carbide tools also helps to control the heat accumulation during the cutting process and avoid deformation of the workpiece due to heat.

Design of tool shape and angle:

In order to better meet the cutting needs of PTFE film, the shape and angle of the tool need to be carefully designed. For example, the rake angle of the tool should be kept above 20~30° to reduce the possibility of tensile fracture from a mechanical point of view and reduce the turning force accordingly.

The cutting edge of the tool should be sharp and smooth to reduce friction and heat accumulation during the cutting process, improve cutting efficiency and workpiece quality.

Optimization of cutting parameters:

In addition to the selection of tool materials, the optimization of cutting parameters is also a key factor in improving the cutting quality of PTFE film. Parameters such as cutting speed, feed rate and cutting depth need to be reasonably adjusted according to the characteristics of PTFE film and tool material.

Under normal circumstances, the cutting speed is recommended to be in a lower range (such as 10~30m/min or 90~225m/min, the specific speed needs to be determined according to the actual situation) to avoid overheating of PTFE and adhesion of the tool. The feed rate also needs to be controlled within an appropriate range (such as 0.05~0.15mm/r) to ensure cutting quality and efficiency.

Cooling and lubrication:

When cutting PTFE film, cooling and lubrication are equally important. Using appropriate cooling media (such as liquid fluoride) for spray cooling can effectively reduce temperature accumulation during cutting, reduce workpiece deformation and the occurrence of sticking.

At the same time, the cooling medium can also play a lubricating role, reduce the friction between the tool and the workpiece, and improve cutting efficiency and tool life.

Jiangsu Taiyuan CNC Machine Tool Co., Ltd. has accumulated rich technical reserves and practical experience with 20 years of experience in heavy-duty CNC lathe manufacturing. The company's products have been widely used in oil fields, geology, mining, chemical industry and other industries, and have obtained GBT, IS0 quality system certification and the honor of national quality trustworthy enterprise. In the design and manufacture of PTFE film skiving machines, the company focuses on technological innovation and quality control to ensure that the products have high precision, high reliability and high efficiency. The company's technical team can provide customized solutions and high-quality after-sales service according to the specific needs of customers.