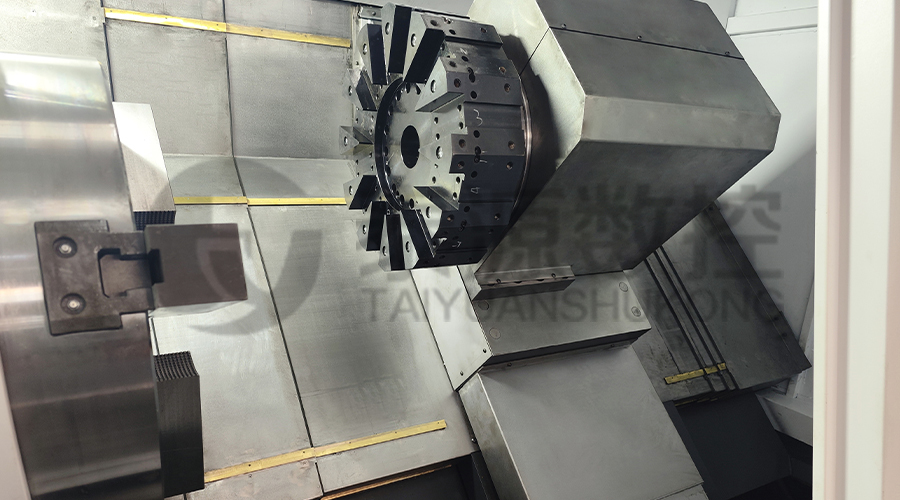

Series:TYSK-NKJ

The machine uses a hydraulic motor, mechanical floating mechanism, and real-time...

Taiyuan CNC is committed to meeting all the needs of users. We provide all kinds of supporting equipment, a one-stop service to save you valuable time.

The machine uses a hydraulic motor, mechanical floating mechanism, and real-time...

The special flexible support mode can effectively reduce the influence of workpi...

The blades are made of high-strength materials and reasonably placed at the exit...

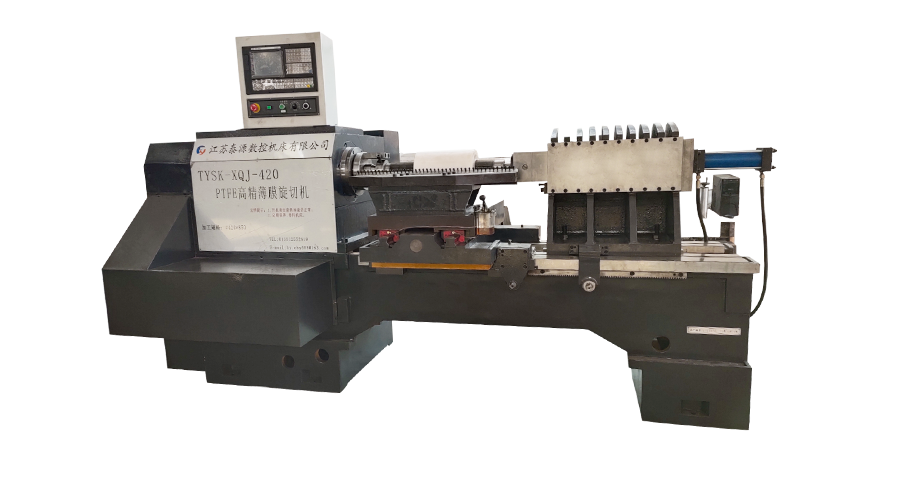

In the rapidly evolving landscape of 2026 industrial manufacturing, the demand for precision in energy infrastructure has reached an all-time high. For facilities engaged in large-scale production, the choice between tra...

In the high-precision manufacturing of fluoropolymer films, maintaining structural integrity at velocity is the ultimate engineering challenge. A Medium & Large PTFE Film Skiving Machine must handle significant rotat...

In the high-stakes environment of oilfield exploration, the longevity of drill pipes and tool joints is directly dependent on the quality of hardbanding applied to resist downhole abrasion. A semi-automatic wear-resistan...

1. Driving force improvement technology

1. High-performance servo drive system In order to improve the driving force of Pipe thread lathe corollary equipment, Jiangsu Taiyuan uses high-performance servo motors and advanced servo drive control technology. The high responsiveness and high power density of servo motors enable the machine tool to provide a smoother and more powerful driving force when performing complex cutting operations. This increase in driving force ensures that the machine tool can maintain continuous stability and efficient processing performance even when processing hard and rough materials.

2. High-power motors and transmission systems In view of the high torque and high load conditions required by pipe thread lathes, Jiangsu Taiyuan also designed high-power motors and their transmission systems, combined with more precise gear sets and transmission shafts, to achieve high-efficiency mechanical drive. This design can not only provide sufficient driving force to meet difficult processing tasks such as deep hole thread processing, but also reduce the power loss in traditional mechanical transmission methods, further improving the output efficiency of driving force.

3. Dynamic adjustment technology During the operation of the pipe thread lathe, the size and material properties of the workpiece will affect the cutting force during the processing. Jiangsu Taiyuan has developed a drive adjustment system based on real-time dynamic feedback, which can automatically adjust the output power and drive mode of the motor. This technology can dynamically adjust the drive system according to the actual changes in the cutting load generated during the processing process to ensure that the driving force is always kept in the best state, thereby reducing the loss of equipment caused by uneven load.

2. Rigidity improvement technology

1. High-strength materials and optimized structural design In order to improve the rigidity of the pipe thread lathe, Jiangsu Taiyuan uses high-strength and wear-resistant materials such as cast iron and steel alloys to enhance the bending resistance and vibration resistance of the machine tool frame. The structural design of the machine tool has also been optimized, and a reasonable reinforcement structure and support scheme have been adopted to minimize vibration and deformation during the processing process. Rigidity-enhanced machine tools can ensure extremely high processing accuracy in complex thread processing, thereby improving product quality and extending the service life of machine tools.

2. Precision ball screw and guide rail technology In pipe thread lathes, ball screws and guide rails are important components to ensure the rigidity of machine tools. Jiangsu Taiyuan uses high-precision ball screws and optimized linear guide rails, which can effectively suppress mechanical deformation and vibration when the machine tool runs at high speed, ensuring the stability and accuracy of the workpiece during processing. The high rigidity of ball screws and guide rails can effectively resist the cutting force generated during processing, reduce the error accumulation of machine tools, and improve the long-term accuracy retention ability.

3. Rubber vibration reduction and sound insulation technology In order to further improve the rigidity of machine tools, Jiangsu Taiyuan also added rubber vibration reduction materials and sound insulation technology to the design of Pipe thread lathe corollary equipment, especially in the base and support parts of the machine tool. This technology can effectively reduce the noise generated during the operation of the machine tool and absorb vibrations from the outside and inside, making the processing process smoother. Through the effective application of the vibration reduction system, the rigidity of the pipe thread lathe during high-precision processing has been greatly improved, thereby ensuring high-quality processing results.

3. How technology helps improve production efficiency and reduce failure rates

1. Automation and intelligent technology Jiangsu Taiyuan has widely applied automation and intelligent technology in the supporting equipment of pipe thread lathes. The intelligent operating system can monitor the working status of the machine tool in real time and issue an alarm in time when an abnormality occurs, reducing the losses caused by human operation errors or equipment failures. The application of automated feeding system and tool changing system can greatly reduce manual intervention, shorten the production cycle, and improve production efficiency.

2. CNC system and processing optimization algorithm The company uses advanced CNC system and processing optimization algorithm, which can automatically adjust cutting parameters and processing paths according to the processing requirements of different workpieces. This technology can not only achieve efficient processing, but also ensure the stability of the machine tool during high-load operation. The high-precision control of the CNC system can effectively avoid errors caused by human operation and reduce the occurrence of machine tool failures.

3. Remote diagnosis and maintenance technology In order to reduce the downtime and maintenance costs of machine tools, Jiangsu Taiyuan has also introduced remote diagnosis and maintenance technology. Through the Internet and cloud computing platforms, the working status of the equipment can be remotely monitored and analyzed. Technicians can find potential faults and troubleshoot them at the first time, reducing the downtime of equipment caused by faults and improving overall production efficiency. Regular remote system updates and software upgrades ensure that the equipment is always in the best operating state and reduces the failure rate.

4. Efficient cooling and lubrication system Jiangsu Taiyuan's pipe threading lathe is also equipped with an efficient cooling and lubrication system. The coolant acts directly on the processing part through a precise spraying system, taking away the high temperature during the cutting process in time, reducing the wear of the tool and the thermal deformation of the machine tool parts. The lubrication system ensures that each moving part is fully lubricated through precise oil distribution, thereby reducing friction and wear and extending the service life of the machine tool.