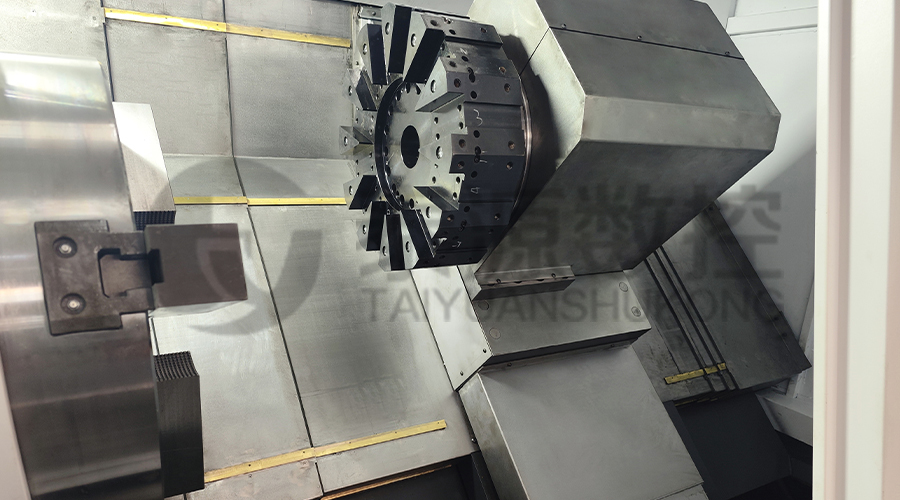

Long, heavy material solutions

The special flexible support mode can effectively reduce the influence of workpi...

Taiyuan CNC is committed to meeting all the needs of users. We provide all kinds of supporting equipment, a one-stop service to save you valuable time.

The special flexible support mode can effectively reduce the influence of workpi...

In the rapidly evolving landscape of 2026 industrial manufacturing, the demand for precision in energy infrastructure has reached an all-time high. For facilities engaged in large-scale production, the choice between tra...

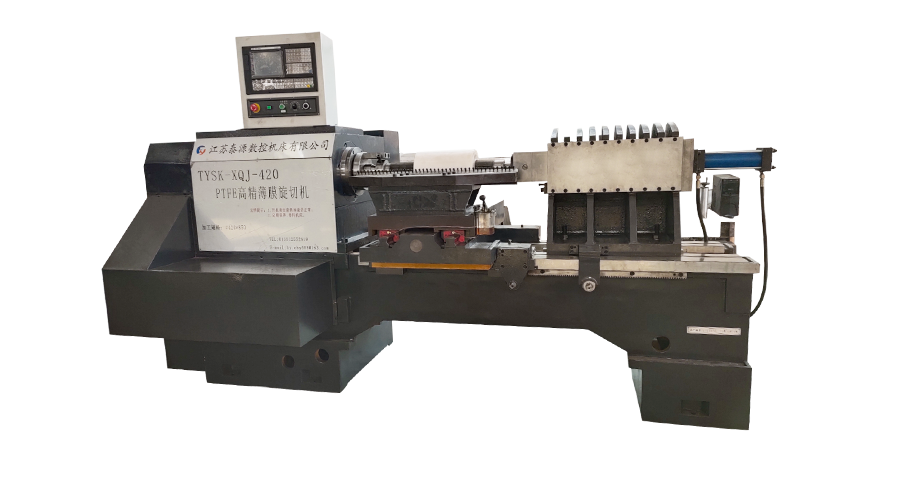

In the high-precision manufacturing of fluoropolymer films, maintaining structural integrity at velocity is the ultimate engineering challenge. A Medium & Large PTFE Film Skiving Machine must handle significant rotat...

In the high-stakes environment of oilfield exploration, the longevity of drill pipes and tool joints is directly dependent on the quality of hardbanding applied to resist downhole abrasion. A semi-automatic wear-resistan...

1. Advanced R&D and design concepts

Jiangsu Taiyuan CNC Machine Tool Co., Ltd. adheres to the business philosophy of "technological innovation, quality first" and is committed to providing customers with high-precision, high-efficiency and high-reliability CNC machine tool solutions. During the research and development stage of Automatic mechanism Lathe Machine for pipe threading, the company invested a lot of resources in market research and technical analysis to clarify customer needs and industry trends. Based on this information, the company uses advanced CAD/CAM technology for 3D modeling and simulation analysis to optimize the machine tool structure and improve processing accuracy and efficiency.

During the design process, the company pays special attention to the rigidity and stability of Automatic mechanism Lathe Machine for pipe threading. Through reasonable layout and structural design, it ensures that the machine tool can still maintain high precision and stability during high-speed operation and heavy-load processing. The company also pays attention to the ease of use and maintainability of the machine tool so that customers can easily operate and maintain it during use.

2. High-quality materials and manufacturing processes

In terms of material selection, the company strictly follows industry standards and corporate specifications, and selects high-quality castings, steel and alloy materials to ensure the strength and durability of machine tools. These materials have excellent wear resistance, corrosion resistance and fatigue resistance, and can maintain stable performance in harsh processing environments.

In terms of manufacturing technology, the company uses advanced CNC machining centers and precision testing equipment to perform precision machining and testing on key components of machine tools. The company also implements a strict quality management system to perform quality control throughout the entire process from raw material procurement, product manufacturing, assembly and commissioning to after-sales service. These measures ensure the manufacturing accuracy and assembly quality of the machine tools, thereby improving the stability and durability of the machine tools.

3. Professional thread processing technology

When processing complex thread structures, the company uses a number of professional thread processing technologies. For example, the company has developed high-precision thread cutting tools and grinding tools to ensure the accuracy and surface quality of the threads. The company also uses advanced thread detection equipment and methods to strictly test the processed threads to ensure that they meet customer requirements and industry standards.

The company also pays attention to stability and efficiency during thread processing. By optimizing cutting parameters, improving cutting technology and adjusting machine tool settings, the company ensures stability and efficiency in the thread processing process. These measures not only improve the processing accuracy and surface quality of the thread, but also shorten the processing cycle and reduce production costs.

4. Strict testing and verification process

After the machine tool is manufactured, the company will conduct a strict testing and verification process on it. These tests include functional testing, performance testing, stability testing and durability testing. Through these tests, the company can comprehensively evaluate the performance and quality of the machine tool to ensure that it meets customer requirements and industry standards.

During the testing process, the company pays special attention to the performance of the machine tool in complex thread processing. The company will conduct long-term continuous processing tests on the machine tool to evaluate its stability and durability under heavy loads and high-speed operation. The company will also conduct strict inspection and analysis of the processed threads to ensure that its accuracy and surface quality meet the requirements.

5. Perfect after-sales service and technical support

In order to ensure that customers can get timely and effective support and services during use, the company has established a perfect after-sales service and technical support system. The company has a professional technical team that can provide customers with on-site installation, commissioning, training and maintenance services.