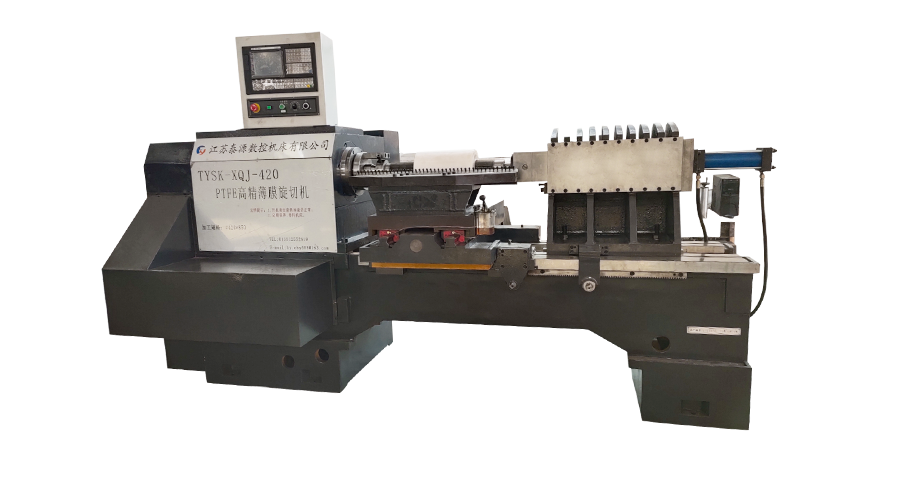

Series:TYSK-NKJ

The machine uses a hydraulic motor, mechanical floating mechanism, and real-time...

Taiyuan CNC is committed to meeting all the needs of users. We provide all kinds of supporting equipment, a one-stop service to save you valuable time.

The machine uses a hydraulic motor, mechanical floating mechanism, and real-time...

In the rapidly evolving landscape of 2026 industrial manufacturing, the demand for precision in energy infrastructure has reached an all-time high. For facilities engaged in large-scale production, the choice between tra...

In the high-precision manufacturing of fluoropolymer films, maintaining structural integrity at velocity is the ultimate engineering challenge. A Medium & Large PTFE Film Skiving Machine must handle significant rotat...

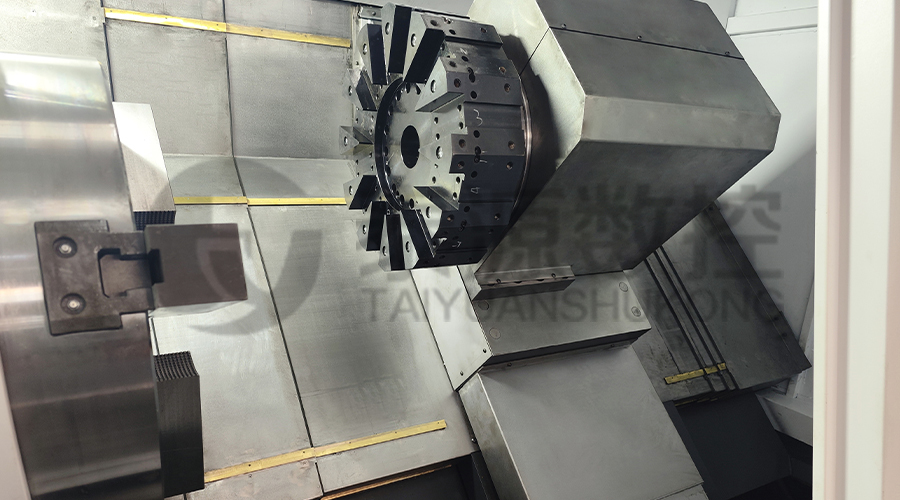

In the high-stakes environment of oilfield exploration, the longevity of drill pipes and tool joints is directly dependent on the quality of hardbanding applied to resist downhole abrasion. A semi-automatic wear-resistan...

The role of drill pipe joint hardband cladding machine

Improve wear resistance:

The drill pipe joint hardband cladding machine uses advanced cladding technology to form a high-hardness wear-resistant layer on the surface of the drill pipe joint. This wear-resistant layer can effectively resist wear and corrosion during drilling, thereby extending the service life of the drill pipe joint.

The wear-resistant layer is usually made of high-hardness, high-wear-resistant alloy materials, which have excellent mechanical properties and fatigue resistance and can maintain stable performance under extreme conditions.

Enhance connection strength:

The cladding process can not only increase the hardness of the drill pipe joint surface, but also improve the bonding strength between the joint and the threaded connection part by optimizing the composition and structure of the cladding layer. This enhanced connection strength helps ensure the stability and reliability of the Screw-On Machine during drilling.

Strong connection strength means that the drill pipe joint is not prone to loosening or breaking when subjected to high torque and high tension, thereby improving the safety and efficiency of the entire drilling operation.

Automation and intelligence:

The drill pipe joint wear-resistant belt surfacing machines provided by Jiangsu Taiyuan CNC Machine Tool Co., Ltd. are usually equipped with advanced automation and intelligent control systems. These systems can accurately control various parameters in the surfacing process, such as current, voltage, welding speed, etc., to ensure the quality and consistency of the surfacing layer.

Automation and intelligent surfacing processes reduce the interference of human factors and improve the accuracy and efficiency of surfacing. At the same time, these systems can also monitor abnormal conditions in the surfacing process in real time and take timely measures to avoid potential quality problems.

Contribution of other special machine tools

CNC pipe thread lathe for couplings:

This lathe is specially used to process the threaded part of the coupling to ensure that its accuracy and surface quality meet the requirements of oil drilling operations. High-precision threads can provide better sealing performance and connection strength, thereby improving the reliability and service life of the Screw-On Machine.

Drill pipe production line and its processing equipment:

The drill pipe production line provided by Jiangsu Taiyuan CNC Machine Tool Co., Ltd. integrates a variety of processing equipment, which can complete the cutting, turning, grinding, threading and other processes of drill pipe. The high precision and stability of these equipment ensure the overall quality and performance of the drill pipe, and provide a strong guarantee for the reliability of Screw-On Machine.

Drill pipe inner hole and outer circle grinder:

This grinder is used for precision grinding of the inner hole and outer circle of the drill pipe to improve its dimensional accuracy and surface finish. This high-precision processing helps to reduce friction and wear of the drill pipe during rotation, thereby extending its service life.

Drill collar outer circle lathe and deep hole drilling machine:

These machine tools are specially used to process the outer circle and deep hole part of the drill collar. High-precision processing can ensure the stability and durability of the drill collar during drilling, thereby improving the efficiency of the entire drilling operation.

Comprehensive Benefit Analysis

Improve Drilling Efficiency:

By providing high-quality drill pipe joint hardbanding machines and other special machine tools, Jiangsu Taiyuan helps oil drilling operations improve drilling efficiency. High-precision machine tools and high-quality wear-resistant layers can reduce failures and downtime during drilling, thereby improving the continuity and stability of drilling operations.

Reducing Maintenance Costs:

High-quality machine tools and wear-resistant layers can extend the service life of drill pipes and couplings, thereby reducing the frequency of replacement and repair. This helps to reduce the maintenance cost of oil drilling operations and improve the overall economic benefits.

Enhance Safety:

Reliable machine tools and wear-resistant layers can ensure the safety of drilling operations. High-precision threaded connections and stable drill pipe performance help avoid accidents during drilling and protect the lives of operators.